CSC Clutch Kit

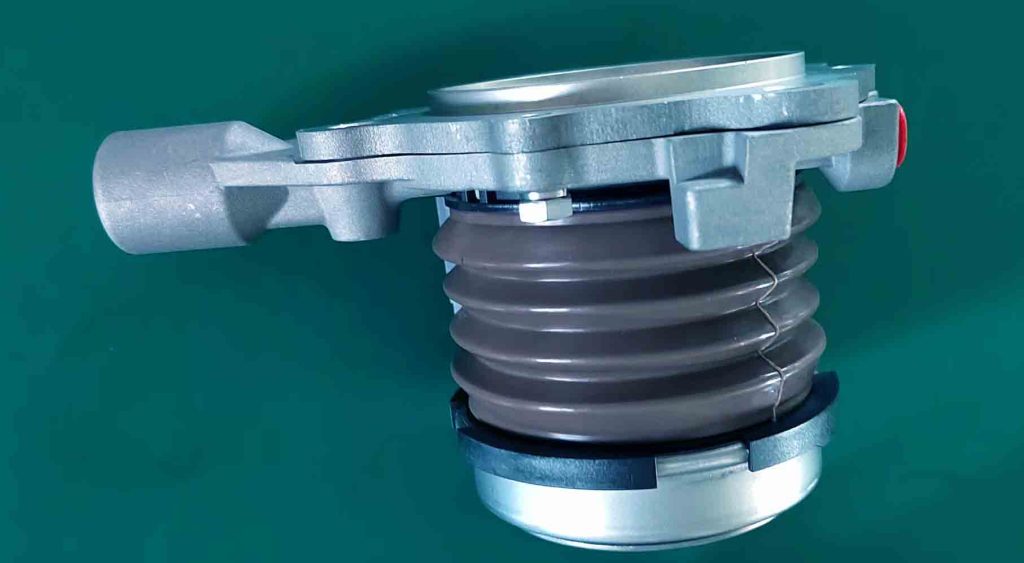

Clutch Industries Heavy Duty Clutch Kit With Concentric Slave Cylinder .

Orient manufactures several CSC Clutch Kit options to suit your needs. These sets come in two distinct weights: a lightweight option with a single clutch (about a thousand grams), and a heavier option with a centrally controlled entire range of motion (around one thousand and seven hundred grams). Please get in touch with Orient immediately if you’re looking for a more cost-effective and trustworthy alternative.

- 20 Years Experience

- TS16949 Certification

- 100% Full Inspection Before Packaging.

Central Slave Cylinder & Pneumatic Release Bearing Supplier & Manufacturer

Provide complete CSC Clutch Kit Technical Tech Assistance.

Make an Enquiry

+ 86-137 5815 0719

Cell / Whatsapp

CSC Clutch Kit

Advantages of Concentric Slave Cylinders

Hydraulic clutch has greater flexibility and reliability, if you compare it with mechanical clutch.

It also has other obvious advantages. For example, the hydraulic clutch can achieve the best and most stable pedal strength. They are more compact. They are made of lighter materials than the standard clutch, and their weight is reduced by at least 70%. This improvement makes it easier to get customers’ approval on some OE projects technically.

The hydraulic release bearing is also called CS c. One of its most obvious advantages is the elimination of release bearing and plug, which means that there is no more deformation of the fork under load.The efficiency of the judicial system will be much higher than before.

Due to the disappearance of bearing, cabbage and guide tube, the whole hydraulic function will be reduced by 70%.

Orient Auto Part’s CSC Clutch Kit is of excellent quality and performance. The CSC clutch kits are available for a wide range of vehicles, with around 90% of European cars being covered.

There are over thousands kit and component numbers available. All types of csc clutch kit, including passenger cars, light commercial vehicles, buses and trucks, as well as construction and agricultural equipment, can be equipped with our csc clutch kit products.

To meet models from all over the globe, and to ensure that all CSC Clutch Kit with stable quality.

Central Slave Cylinder

Hydraulic Throwout Bearing

Pneumatic Release Bearing

Clutch Release Bearing

Clutch Disc

Clutch Cover

Belt Tensioner Pulley

csc clutch kit

CSC Clutch Kit Benefits

Choosing a CSC Clutch Kit is a good choice for a number of reasons. The benefits include cost, weight, installation, and compatibility. Here are some things to consider when choosing one for your vehicle. You can read this article to learn more. After reading this article, you’ll know whether or not CSC clutch kits are a good choice for your vehicle. The CSC Clutch Kit replaces the clutch cover diaphragm and is equipped with an integrated release bearing. It has the advantage of being in direct contact with the clutch cover diaphragm, which improves hydraulic system efficiency.

Cost

A CSC clutch kit is a relatively inexpensive alternative to a full-on rebuild. These kits contain all of the parts necessary to replace the clutch, including the slave cylinder and release bearing assembly. The only major difference between a CSC and a fully-replaceable clutch is the cost. There are many benefits to using a CSC.

A concentric slave cylinder (CSC) contains all four of the major parts of a traditional clutch, resulting in a compact and lightweight design. Because of this, vehicle manufacturers have chosen to incorporate this design into the production of their transmissions. However, the seal and bearing assembly’s guide tube can become corroded, dirty, or contaminated over time. The CSC clutch kit eliminates the need for a separate bearing or release bearing, which can be expensive and potentially dangerous.

Weight

When deciding on a new clutch for your car, it’s important to determine the weight of the kit you’re looking at. Compared to the stock clutch, the CSC kit is heavier, but it is still not as grabby as the factory clutch. You’ll want to engage and disengage the clutch at a low pressure, which may take some getting used to. The weight of the kit depends on the engine and transmission used in your vehicle.

A hydraulic release system eliminates the need for a release bearing and a fork. It also reduces the pedal load while increasing efficiency. In addition, the CSC clutch kit is lighter than the original system because it does away with all the other parts. While it’s true that the CSC is heavier, it is much more affordable than a traditional clutch kit. The CSC clutch kit weighs about 0.88 lbs.

Installation

Before attempting to install a CSC clutch kit, there are a few things you should do first. Make sure the input shaft is clean and free of damage or excessive wear. Then, install the CSC in its proper location. To begin installation, make sure the spigot bearing is seated correctly in the transmission’s input shaft. If it is not, the transmission may suffer damage. Be sure to clean the clutch face and pressure plate surfaces thoroughly with Thinners. Be careful not to grease any surfaces or touch them with dirty hands. To bleed the CSC, follow the instructions in the manual that came with the CSC.

The release bearing should also be replaced if needed. The clutch kit contains the release bearing, which is essential for proper operation. This will prevent the need to purchase the release bearing separately. However, the technician should also purchase two release bearings in order to avoid unnecessary expenses. Once the release bearing has been replaced, the technician can move onto the next step, which is fitting the CSC. Then, the CSC and the transmission must be flange mounted to the engine.

Compatibility

When determining the proper CSC clutch kit for your vehicle, you need to consider how the kit will fit. Most failures of the CSC occur during the fitting process or right after bleeding the system. To minimize the risk of error during installation, you should always follow the manufacturer’s procedures and follow the recommended torques. It is also critical to follow the manufacturer’s fluid recommendations. Following these steps can help you ensure the best compatibility with your vehicle and avoid costly repairs.

A hydraulic clutch release system eliminates the conventional clutch release bearing and fork, reducing the weight of the clutch. It also reduces the pedal load. This system has a few advantages over a conventional release bearing and clutch lever. Unlike conventional release bearings, which must be manipulated by a lever, a hydraulic clutch system eliminates both of those components. These kits are designed to be compatible with vehicles that use a full-hydraulic system.

You might be wondering what is the specification of CSC Cluting Kits. Hopefully, this article will answer that question. After all, it is your car, so you need to know how to replace it correctly. So, let’s get started. First, let’s define what exactly is a concentric salve cylinder. This component is used in a clutch, which is why it is sometimes referred to as a ‘CSC’.

The release bearing assembly is an integral part of a CSC. If it fails to release properly, the clutch will fail, resulting in an expensive repair bill. Some CSCs are designed with elaborate elements that enhance their operation.

Among these are peak torque limiters and anti-vibration units. In addition to the release bearing assembly, there is another component of the CSC. If the clutch is contaminated, it may require a replacement by a garage.

A second type of CSC Clutch Kit requires a mechanical aptitude. It requires a bolt-on installation. This type of kit is designed to replace OEM clutch concentric slave cylinders without causing any damage to the vehicle.

If you’re not familiar with CSC clutch kits, you’re not alone. These clutch kits are among the best on the market.

The CSC stands for Concentric Slave Cylinder, and they’re made to replace the release bearing and cylinder in your car.

The CSC kit is designed to reduce the number of parts you’ll need to replace, thereby maximizing drivetrain efficiency. A CSC clutch kit also enables you to control the clutch with less pedal power.

The CSC is constantly being improved and updated. By renewing your CSC, you’re guaranteed to have the latest design installed in your car.

However, it’s important to remember that it’s important to replace the entire clutch if the CSC fails, as leaking fluid can damage the newly fitted clutch, and lead to an expensive rectification bill for your garage. You might also end up with a disgruntled customer.

Another key feature of the CSC clutch kit is its convenience. The CSC features four components in one, making it easy to install.

The concentric slave cylinder is the easiest to maintain, and vehicle manufacturers prefer to incorporate it into their transmission design. Another benefit is that it eliminates the need for a clutch fork.

Lastly, the CSC provides more accurate release bearing travel. It also helps to provide better alignment geometry and a closer fit to the transmission.

In addition to being bolt-on compatible with OEM clutches, the CSC also features an internal type slave. The height of the clutch stack must be between 81-83mm.

When fully bolted to the flywheel, the clutch/flywheel stack height is 81-83mm. An OEM clutch is higher.

It is self-adjusting, so it won’t need to be adjusted throughout the life of the clutch. For a complete installation, a new clutch master cylinder should be installed along with the CSC.