Slave Cylindar

Slave Cylindar: As you know, for Slave Cylindar, the leakage and refueling occur internally and externally. In order to ensure the smooth use of your clutch, the master cylinder and Slave Cylindar types designed by us fully meet their matching requirements. No matter in the clutches of any vehicle model, our team leaderead more>>>

Slave Cylindar

For gearboxes with fork-release clutches, the pump body is made of a specific plastic and is shielded by a corrugated rubber dust cover. The advantages of corrosion resistance, durability, and light weight of the plastic distributor pump over the conventional cast-iron distributor pump fulfill the demands of contemporary lightweight auto parts.

Advantage:

- Reduced weight

- Reduced parts

- Corrosion resistance

- Reduces friction

Concentric Slave Cylinder

Pneumatic Release Bearing

Clutch Release Bearing

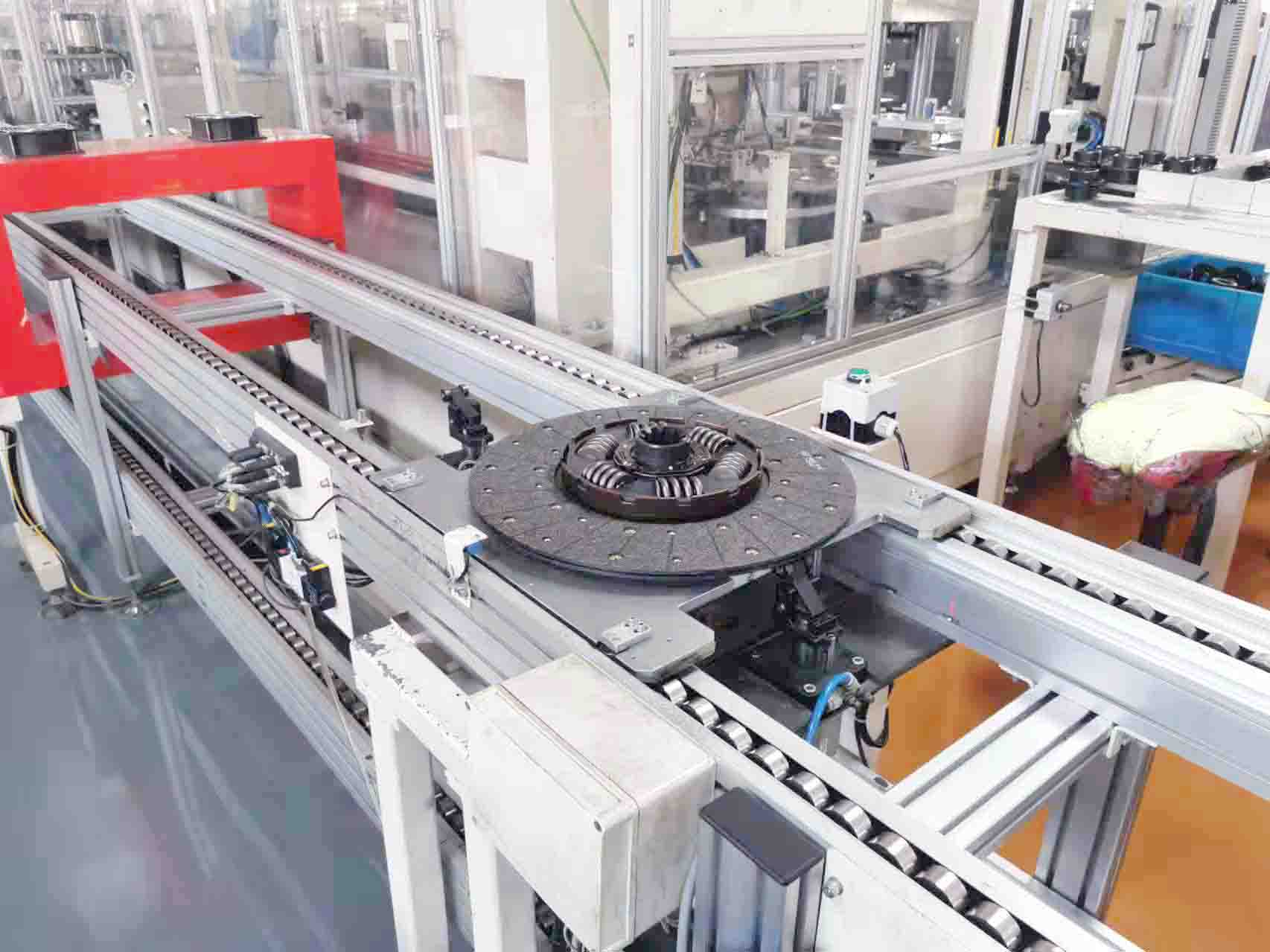

Clutch Disc

Clutch Cover

Belt Tensioner Pulley

Slave Cylindar

Orient is your trust hydraulic throwout bearing supplier in China which has made two efforts to ensure strict quality control. A complete dynamic recording mechanism for supplier quality has been established based on raw material evaluation. After confirming that the quality of raw materials provided by suppliers meets the requirements, raw materials can be accepted for storage, ensuring product quality stability from the source. Simultaneously, all produced bearings are subjected to a 100 percent comprehensive inspection before shipment, and only the inspection data can be sent to customers if they meet the requirements of the drawings. As a result, quality will not be an issue for you from the moment you call Orient with your order.

Slave Cylindar

Keep the slave cylinder clutch clean to prevent damage. It should be cleaned frequently with fresh water. Additionally, you must frequently cleanse it with new hydraulic fluid. If you find leaks, fix them right once to prevent dirt and debris from getting into the system and harming other components. Additionally, you should routinely inspect the slave cylinder clutch to detect issues early.

Slave Cylindar

Your current OE manual clutch system can be directly replaced by the manual slave cylinder clutch. A unique piston and seal design maximizes the rider’s connection to the engine, and the billet aluminum housing is forged for utmost durability. The cylinder is made to work with either aftermarket or original equipment manual clutch systems.

slave cylinder that is pull-type

The stroke of the pull type slave cylinder clutch is longer than that of ordinary versions. Additionally, it is composed of billet aluminum and has a tough anti-corrosion treatment on it. A pushrod made of stainless steel completes the assembly. The “pull type” slave cylinder is made for uses where long stroke cylinder movement is required.

An very effective method of clutch actuation is the “pull type” slave cylinder clutch. It has a push rod made of stainless steel with a longer stroke than standard cylinders. Additionally, it has a billet aluminum body plated with a strong anti-corrosion finish and a push rod that is completely rebuildable.

The slave cylinders are positioned externally, outside the bell housing of the gearbox. Pushrod, piston, and an internal spring are all part of them. A mushroom-shaped bushing is used as the pushrod’s tip to lessen surface wear. Additionally, it has a release bearing that keeps the diaphragm spring in preloaded contact.

slave hydraulic cylinder: Slave Cylindar

Look no farther if you want to replace your outdated manual slave cylinder clutch. The most rigorous riding conditions and highest levels of racing have demonstrated the dependability of manual slave cylinders, which are direct bolt-on OE replacements. These cylinders have robust pistons and seals as well as billet aluminum housing that has been hard anodized. They fit both bikes and ATVs without losing quality or durability because they are made for OE manual clutch systems.

OEM slave cylinders are typically constructed of cast aluminum, however the hydraulic slave cyclinder clutch is made of billet 6061 aluminum that has been hard anodized. As a result, it is stiffer than OEM and feels more attached. Additionally, this design does not require removing the clutch cover to adjust the clutch.

It’s possible that the internals of the slave cylinder are malfunctioning if the clutch lever is difficult to pull. In this instance, as the lever is pulled in, fluid rushes past the edge of the piston and avoids it. The engine may accumulate fluid as a result of this.

An additional choice is a manual slave cylinder. The manual slave cylinder is comparable to the hydraulic slave cylinder, however it is simpler to maintain. When the internal components become harmed with this system, you can quickly replace it. If you don’t like the hydraulic slave cylinder, you can choose a manual one instead.

Email: [email protected]

Whatsapp/Wechat: +86-13758150719

Contact Us Now

Slave Cylindar