Concentric Slave Cylinder Installation

Concentric Slave Cylinder Installation This post will explain how to properly install and bleed a concentric slave cylinder. Additionally, you will discover how to eliminate a concentric cylinder. Installation and removal of a concentric cylinder is relatively simple. The initial step involves removing the clutch coverread more>>>

Concentric Slave Cylinder Installation

Concentric Slave Cylinder

Pneumatic Release Bearing

Clutch Release Bearing

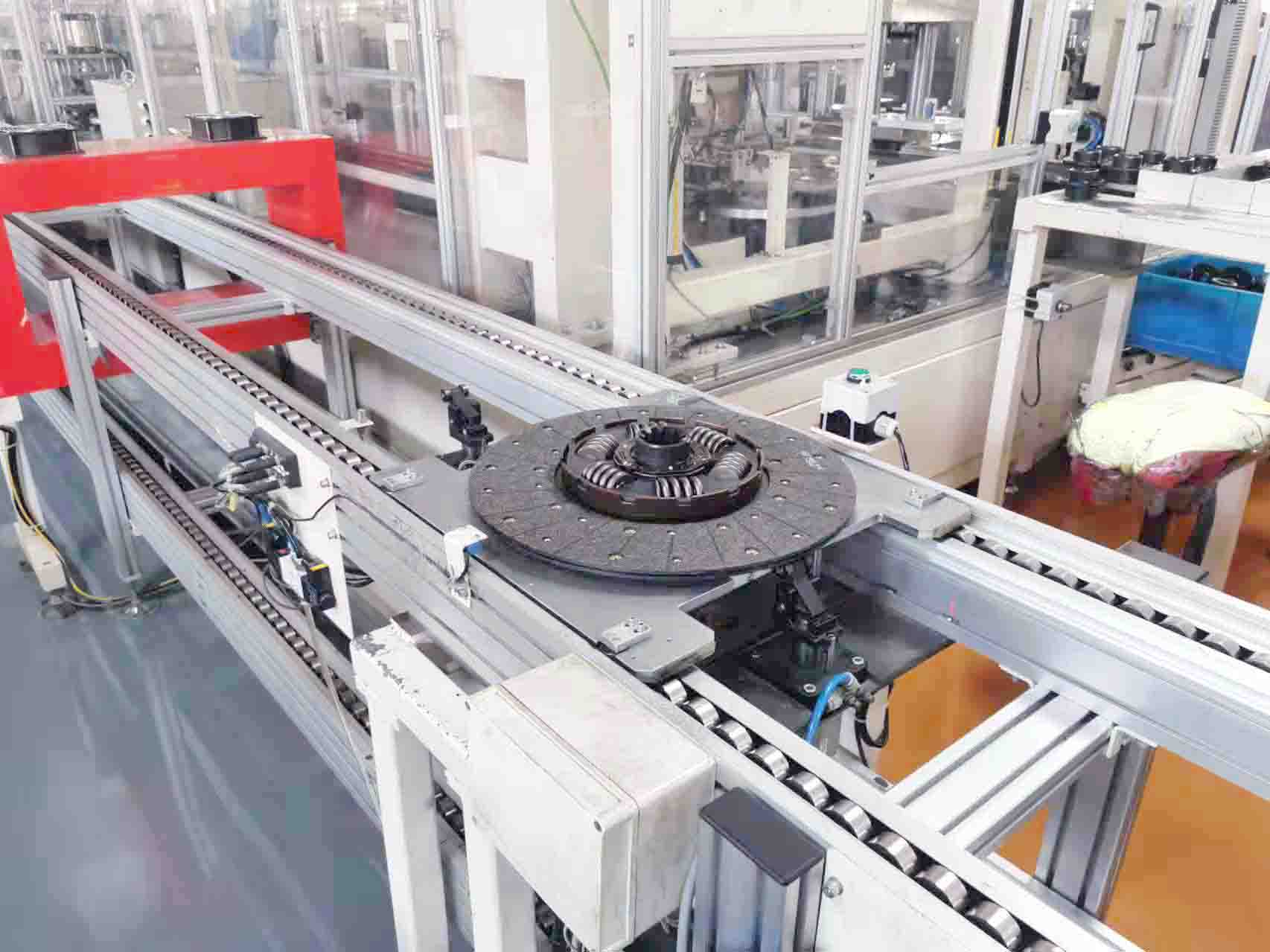

Clutch Disc

Clutch Cover

Belt Tensioner Pulley

Concentric Slave Cylinder Installation

Orient is your trust hydraulic throwout bearing supplier in China which has made two efforts to ensure strict quality control. A complete dynamic recording mechanism for supplier quality has been established based on raw material evaluation. After confirming that the quality of raw materials provided by suppliers meets the requirements, raw materials can be accepted for storage, ensuring product quality stability from the source. Simultaneously, all produced bearings are subjected to a 100 percent comprehensive inspection before shipment, and only the inspection data can be sent to customers if they meet the requirements of the drawings. As a result, quality will not be an issue for you from the moment you call Orient with your order.

Concentric Slave Cylinder Installation

This post will explain how to properly install and bleed a concentric slave cylinder. Additionally, you will discover how to eliminate a concentric cylinder. Installation and removal of a concentric cylinder is relatively simple. The initial step involves removing the clutch cover. When removing the clutch cover, the input shaft should not come into touch with the cover.

Concentric Slave Cylinder Installation

Certain actions must be followed while installing a concentric slave cylinder to ensure the correct connection. First, verify that the slave cylinder is fitted to the engine correctly. Then, you must connect the hydraulic line to the slave cylinder atop the transmission. After installing the slave cylinder, hydraulic bleeder fluid should be used to ensure that the hydraulic system is correctly lubricated.Concentric Slave Cylinder Installation.

The external slave cylinder is exterior to the transmission bell housing and consists of a pushrod, piston, and internal spring. To reduce surface wear, the pushrod is topped with a mushroom-shaped bushing. The pushrod is crucial to the operation of the hydraulic system because its length must correspond to that of the diaphragm spring.

Before it can be filled with hydraulic fluid, the slave cylinder must be fitted in the clutch bell housing of the transmission. Transmission and clutch must also be flange-mounted to the engine. The hydraulic fluid should be filled in accordance with the manufacturer’s instructions. The hydraulic system should then be bled using equipment readily available at home.

The master cylinder controls a complex mechanism known as a concentric slave cylinder, also known as a central release bearing. When the clutch breaks, it is essential to also replace the concentric slave cylinder to avoid expensive repairs. You should not replace a concentric slave cylinder on its own, as doing so could cause the clutch to malfunction.

Concentric Slave Cylinder Installation

Bleeding a slave concentric cylinder

A concentric slave-cylinder can be difficult to bleed. The precise location of the bleed screw must be known. You should also have the proper equipment, such as a pressure bleeder, on hand. One is available at most brake shops. Once you have the required equipment, carefully follow the instructions.

Disconnect the coupler first. Additionally, gravity can be used to bleed the transmission line. But it may be disorganized and ineffective. Additionally, there will always be stale fluid in the slave transmission. Therefore, you should routinely bleed your cylinder. Before applying new fluid, check for leaks to simplify the procedure.

Concentric Slave Cylinder Installation

If you don’t prime a concentric slave cylinder with fluid beforehand, bleeding it can be tough. This is due to the fact that you will be drawing air into the clutch mechanism. Air bubbles will produce intermittent pressure, which can result in a failed clutch. To resolve this issue, you can seal the line with a bleed screw or a reservoir lid. However, it is vital to realize that air bubbles may be the result of a system breach.

Concentric Slave Cylinder Installation

Before bleeding the concentric slave cylinder, you must remove the transmission from the vehicle. The pedal strokes will expel air and cause the bearing to move through its stroke. When you apply the clutch pedal again, you must bleed the master cylinder and slave cylinder with the fluid that was previously bled.

You can borrow a vacuum pump from an auto parts store if you lack one at home. Vacuum pumps make this task considerably easier. Once the slave cylinder is clean, the vacuum pump bleeder screw can be opened and a vacuum hose inserted.

Concentric Slave Cylinder Installation

Refer to your service manual to identify the bleeding valve on the slave cylinder. A line wrench may be used to loosen the bleed screw. Next, press the bleeder valve using the transparent hose. The liquid will drain into the bottle of soda. Continue this method for an additional one to three minutes.

Throughout the bleeding procedure, you must maintain the clutch pedal in its fully depressed position. This stops the hydraulic fluid from traveling too far, hence preventing air leaks. The diameter of the bleeder valve is normally 8 millimeters. Ensure that the valve is not bled more than necessary.

Concentric Slave Cylinder Installation

Removing a slave cylinder that is concentric

Disconnecting the hydraulic line from the slave cylinder is the first step in removing a concentric slave cylinder. You can accomplish this with a suitable wrench. The bolts should not be deformed or pointed. Then, remove the air leakage plug. This process requires the use of specialist equipment as well.

Concentric Slave Cylinder OE List

For JEEP

| 619002 |

| 619003 |

| 619007 |

| 619008 |

| 4638464 4638465 4728060 |

| 619004 |

For Man

| 81.30550-0115 81.30550-0250 81.30716-6105 |

| 81.30550-0074 81.30550-0079 |

| 81.30550-0272 |

For Scania

13208100

1522377

For Audi & Golf

0A5 141 671

20157577

02M 141 671B

0A5 141 671 H

0A5 141 671 L

0A5 141 671 N

02F141671A

02F141671B

0C6 141 671

0C6 141 671 C

0C6 141 671 D

0C6 141 681 C

For Chery

519MHA-1602501

For Dodge

| 4899035AB |

| 5038118AB |

For FIAT

| 55183321 |

| 55186498 60802015 |

| 55180328 55184437 55209138 |

| 55190965 |

| 55190965 |

| 46516373 55184041 |

| 55199563 55228666 55230696 55238035 55248403 |

| 55210245 55214650 55240573 55243919 |

| 55224014 55224015 55232692 55232693 55240571 |

55354177 5679356 |

| 55197680 |

| 55209342 |

| 55181216 55183501 |

| 46823418 |

For Land Rover & Jaguar

| UUB000010 UUB000050 UUB000070 |

| UUB 105300 UUB 105301 |

| UUB100192 UUB100193 UUB100194T |

| LR014290 UUB000100 UUB000160 |

| XR8Z-7A508-AA XR83-7A564-AA XR83-7K564-AA |

For SsangYong

| 3036021100 3036021300 3036021301 |

| 30360-34001 |

| 3036008100 3036008200 |

For Volvo

| 21580956 21580968 21580977 |

| 21459182 21580965 21934651 21934653 |

31259445 09181326 9181322 |

| 31259446 31259889 8636105 |

8675052 LR022452 |

For Citroen & Peugeot

| 16112 72980 2041 83 2041 89 |

| 2041 95 |

| 2041 82 96553 06480 |

| 2041 A6 2041 90 2324A078 2324A080 05273431AA 05273431AB |

| 2041 A1 2041 A4 2041 84 2041 99 9652574780 |

| 2041 A5 9677933380 9683093380 |

| 2041 A2 2041 A3 2041 85 2041 98 9661718680 |

| 9818310480 |

| 9675000480 |

For Hyundri

| 41421-38000 |

| 41421-38500 |

| 41421-24300 41421-24350 |

| 41421-24400 41421-3B000 |

For Ford

| YL5Z 7A508 AA F87Z 7A508 AC | |||||||||||||||||||||||

| F87A-7A543-AC XL34-7A543-AB F87A-7A508-AB | |||||||||||||||||||||||

| F87Z-7A508-AA F37A-7A543-CB F47A-7A543-AA F57A-7A543-AD F87A-7A543-AC | |||||||||||||||||||||||

| F1TA-7A508AA F4SC-7C522-BA F1TZ-7A564-A | |||||||||||||||||||||||

| XS41 7A564 EA 1021237 1075776 96WT7A564BB | |||||||||||||||||||||||

| 2S65-7A564AA | |||||||||||||||||||||||

| 1212061 1474323 2S61-7A564-CA 2S61-7A564-CB | |||||||||||||||||||||||

1141597 2S61-7A564-AA | |||||||||||||||||||||||

| 7113400 94ZT7A564AA 94ZT7A564AB 006141165C | |||||||||||||||||||||||

| D951003 E5TZ7A564A | |||||||||||||||||||||||

| 1504696 7113401 94ZT-7A564-BA 94ZT-7A564-BB | |||||||||||||||||||||||

1469873 8C11-7A564-AB

|

For Mitsubishi

| MN168395 418037410 |

SF-13197 ME523197 |

ME539937 ME538976 ME540229 ME523208 |

| ME540224 |

| ME540228 |

For Suzuki

| 23820-64J00 |

93193600 23820-79J00 |

| 23820 78M00 |

For Toyota

| 31400-59025 |

| 31400-0W010 31400-79005 31400-79015 |

| 31400-19005 31400-59005 31400-59015 |

31400-39006 31400-39005 |

For Mercedes – Benz

| 0002541808 0002541408 | |||||

| 0002542508 0002541608 0B7141671 | |||||

| 0002541508 | |||||

A0002541708 0B8141671 | |||||

| A0002543608 A0002544608 | |||||

| 0002540420 0022506615 0022505115 0022502915 | |||||

3182600141 A 0022505515 | |||||

| 0002506215 | |||||

A 0022505815 A 0022507415 | |||||

| A 0022505315 A 0022505715 | |||||

A 0022506015

|

For Nissan & Renault

8200124021 7700110348 8200283479 | ||||||||||||||||||

30620 9222R 8200046102 8200855816 | ||||||||||||||||||

7700107635 | ||||||||||||||||||

30620-6S301 | ||||||||||||||||||

8200102464 8200148787 8200205238 8200764610 8200764612 | ||||||||||||||||||

30620 6299R 30620 6822R 8200213679 8200764616 8200805652 8200842575 | ||||||||||||||||||

30620-BN700 30620-BN710 30620-00QAB 30620-00Q0A 8200046103 8200764613 | ||||||||||||||||||

8200116459 8200341798 30620-AE800 | ||||||||||||||||||

30570-00QAB 8200785483 | ||||||||||||||||||

30620 2443R 8201035313 | ||||||||||||||||||

306A1 JK40D 306A1-JK40E | ||||||||||||||||||

30 62 028 99R

For Chevrolet

|

Concentric Slave Cylinder Installation

Email: [email protected]

Whatsapp/Wechat: +86-13758150719

Contact Us Now

Concentric Slave Cylinder Installation